The Only Guide for Sandblasting

Wiki Article

The 8-Second Trick For Grit Blasting

Table of ContentsLittle Known Questions About Harbor Freight Sand Blaster.The Greatest Guide To Harbor Freight Sand BlasterGetting The Black Diamond Blasting Sand To WorkThe 6-Second Trick For Sand Blaster For SaleThe smart Trick of Portable Sandblaster That Nobody is Discussing

In all situations their use can present severe risk to operators, such as burns due to forecasts (with skin or eye sores), drops because of walking on round shot scattered on the ground, exposure to harmful dusts, warm exhaustion, production of an explosive environment, and exposure to excessive noise.Blasting lead-based paint can load the air with lead particles which can be harmful to the worried system. In the United States the Occupational Safety as well as Health And Wellness Administration (OSHA) requireds crafted services to possible hazards, nonetheless silica sand remains to be allowed also though many frequently made use of blast helmets are not adequately efficient at safeguarding the blast driver if ambient levels of dust go beyond permitted limitations.

To offer the materials the appropriate worn appearance sandblasting is made use of.

Sand Blaster For Sale Things To Know Before You Buy

's Fair Profession Facility carried out a study amongst 17 textile business that showed really couple of were mindful of the dangers created by manually sandblasting jeans. In 2013, research asserted that in China some manufacturing facilities producing worn-look jeans are involved in different non-compliance with health and wellness and also security policies.Introduction This short article provides comprehensive information concerning sandblast closets. You will find out how these sandblast cabinets are made and their materials of building in addition to applications, advantages, and downsides. Check out better to address questions like: How do sandblast cupboards work? Why should you select sandblast closets rather than other cleansing as well as surface area preparation equipment? What can sandblast closets do? How can you optimize your manufacturing operations with unpleasant blasting devices? Exactly how are sandblasters made? What are the materials of construction? How do I specify a sandblast closet when purchasing or submitting an RFQ? What types of abrasives, shot as well as blast media are used? Can I throw away, reuse, and also reuse made use of abrasives, shot, and blast media? Does the blast media wear out sandblast closet parts? And also far more Sandblast Cabinet from Great Lakes Finishing I.

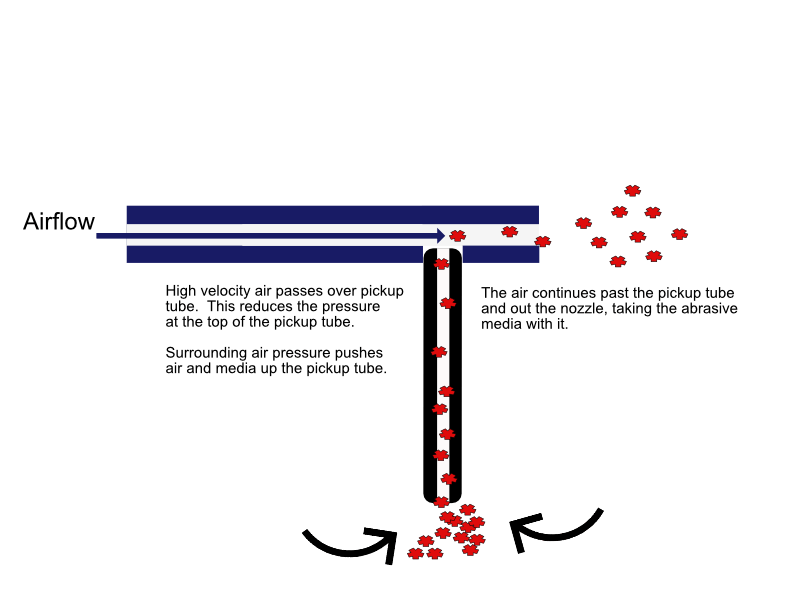

Suction blasters are commonly utilized in short-run or light production, upkeep, and remote field applications. The much less aggressive nature of suction or siphon blasters raises the moment to strip or clean components. On the benefit, the lower aggression decreases the wear price of the components within a suction gun. clemco sandblaster Suction blaster components tend to last longer minimizing blast equipment maintenance prices.

Sandblasting for Beginners

Cleaning agents can be included in the water to loosen down payments, liquify oils or greases and increase the cleaning procedure. sandblasting. Corrosion inhibiting agents can be contributed to the water to avoid rusting of damp steel after the blowing up process is full. If rust special info suppressors are not added to the water, after that the steel should be dried, oiled, or painted after blasting to avoid corrosion development.They subdue 50% to 85% of the dirt created. The water ring or halo nozzles provide less dust control than the water induction or shot nozzles. One downside of slurry guns is tidying up the muddy mess created in area applications. Slurry blast devices is tiresome for drivers to carry and take care of because a hefty water hose is connected.

Vapor unpleasant blast systems offer the greatest degree of dust suppression, up to 95%. The unpleasant slurry takes a trip with a blast tube to the slurry blasting nozzle.

Get This Report on Pressure Washer Sandblaster

Ice blowing up cabinets need to be designed to handle the cooler media, in addition to the condensation on lines, cabinet wall surfaces, pots, as well as vessels. The webpage materials of building can not include kinds of plastics or metals, which end up being breakable at lower temperatures. Dry ice is gentler as well as softer than plastic media. Dry ice media can be in two kinds: pellet and also shaved or snow-like flakes.Ideally, the media as well as dirt created from blasting parts is included within the closet as well as filtration system. Blast cabinets develop leaks as seals damage with time. Dripping around doors is a typical problem because cupboard doors are not constantly clamped limited around the entire periphery. One leading maker, Titan Abrasive Equipments, has established a patent-pending innovation for "leakage or warp" evidence blast closet doors.

Fastening permits the components to be much more easily removed for cleansing, repair service, and also substitute. Welded blast cupboards tend to be more closed with less leakage of blast media and dust right into the shop, but substitute of used closet sides or bases is challenging. The abrasive blast stream puts on the base and sides of the closet in time.

Examine This Report on Sand Blasting Sand

What Are Blast Cupboard Products of Construction? Blast cupboards for completely dry or air blasting are constructed from steel with powder layers or industrial paint. Wet blasting cupboards are made from even more corrosion-resistant products such as stainless-steel. In particular dry blowing up applications such as medical instruments as well as medical implants, stainless-steel building products could be used to prevent iron contamination of a surface area.Steel components or steel shot affecting stainless steel parts can move steel to the stainless surface area, which can modify passivation as well as lead to corrosion externally. Wear-resistant steel linings are purposefully put within blast chambers to lower wear of the blast equipment (dustless blasting near me). Wear-resistant alloys consist of manganese steels such as Manganal as well as nickel and also chromium white cast irons such as Ni-Hard alloys.

Report this wiki page